Save $35-65 a month

Plus $300 for the cost of the normal installation parts required with OTHER manufacturers' boilers.

Hyprotherm FLRH-185

Brick or Barn Red and Black corners and roof trim

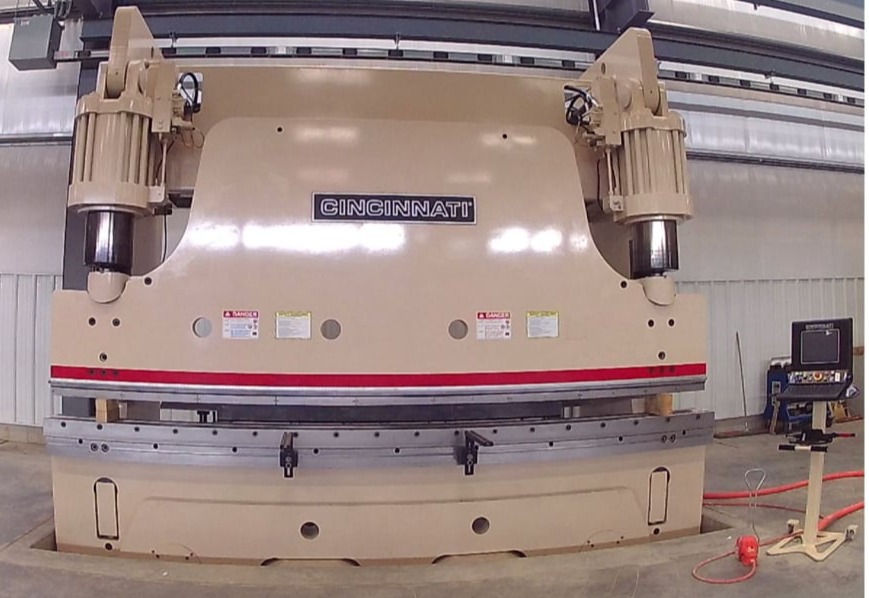

430-TON Press Brake

Hyprotherm FLRH-265

50% larger firebox than the FLRH-185 but is only $1300 more which I think is a great deal for a 50% larger boiler. This is the one I chose so that I could get enough wood in it so that it would burn for 24 hours, which means loading it just once a day! This is real nice because you don't know when it might be sleeting, freezing rain, blizzard conditions or who knows what else. Once a day is always better than the typical two times a day loading.

What you will achieve depend on many factors, including how well your building is insulated, how cold it is and it there is a wind blowing plus the type of wood you are burning plus how warm you want to keep the building and it you are heating your domestic hot water..

There is no negative to get a bigger furnace because it is just like getting a larger propane or oil tank. It holds more fuel, so they fill it less often and in this case, you are doing the filling!

An older model, with a smaller door, heating an old 1940s home, as featured in Holmes and Holmes Magazine.

FLRH-265 in Burnished Slate all over

Barely any visible smoke from my personal 15 year old boiler.

Some older FLRH furnaces, with the smaller loading door, in assorted colors, ready to be shipped

17 different colors to choose from ALL FREE!

A simple collage of photos

Hyprotherm FLRH-300 Boiler

Hyprotherm FLRH-350 Boiler, shown with an optional cylinder that goes into the firebox to mount an aftermarket burner, such as waste oil, propane or heating oil. This comes finished with a flange to mount any aftermarket burner to provide heat when you are away.

We also have this available protruding out the rear, where the pump and fan are and in that case we remove the rear door to give more room for the burner.

These are also available as an option on our unique top loading furnaces and boilers.

100% PERFECT FEEDBACK!

A proud eBay member since 1998; 23 YEARS!

NOW 912 Ratings with 100% POSITIVE and 20 POSITIVE in the last 12 months!

https://www.ebay.com/fdbk/feedback_profile/aware

Member since: Apr-05-98

Hyprotherm FLRH-185

Looks pretty today! However, a black front; the same color as the doors will look great forever!

Hyprotherm Boiler, with pump, fan with damper, aquastat, wiring, 110 V plugs and induction blower switch and extra port (for another pump), fill line, shown with the full-sized rear door open, for easy access.

Plus $300 for the cost of the normal installation parts required with OTHER manufacturers' boilers.

My boiler and wood shed

Note only a small trace of smoke!

Hyprotherm Hot Air Furnace with the Preferred black front

No smoke stains will EVER show! Looks GREAT FOREVER!

Top Loading Forced Air Furnace

1991 Boiler in Arkansas

One of the first ever sold in the U.S.

We were indeed the first to build outdoor wood boilers in the US!!

This was before we used colored metal siding.

STILL IN USE TODAY; 30 YEARS OLD!

This is a fire just 2 minutes after the forced-air induction blower came on -igniting the gases from the wood!

You can see that the wood itself is not burning yet. The flames are AROUND the wood!

This is a Wrecked Boiler that tumbled down the highway, end over end and DID NOT LEAK AFTER!!

SUPER STRONG with only sheet metal damage!

TRENCH FOR BURYING YOUR INSULATED PEX PIPE

ALWAYS buried below the frost line in your area for the best performance!

Stress cracks occur in stainless steel and cause leaks into the firebox!

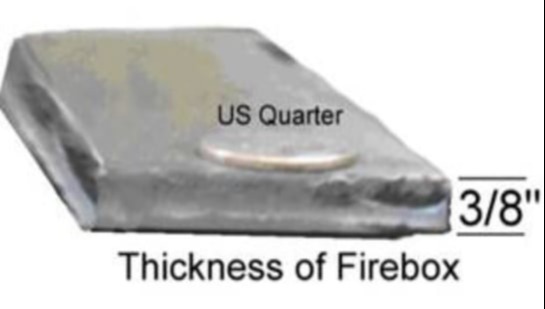

This photo shows the thinness of a typical stainless Steel Firebox; just 1/16 of an inch.

The industry standard for a steel firebox is four times thicker at just 1/4"

Hyprotherm's STANDARD firebox is 50% thicker at 3/8"

Hyprotherm's Heavy Extreme Duty Firebox is a whopping HALF INCH THICK, as demonstrated by the far right drill bit's size, for only $399!

PROUDLY Made and built in the USA with U.S. steel!

Catalytic Converters for Sale for Outdoor Wood Boilers from $749 without 24" extension and chimney cap.

See how well these work!

Transition for heat exchanger to enable and much larger heat exchanger to be used!

5 foot, 5/8" thick heavy duty poker included for FREE with all models

(except Econo FLRH-85)

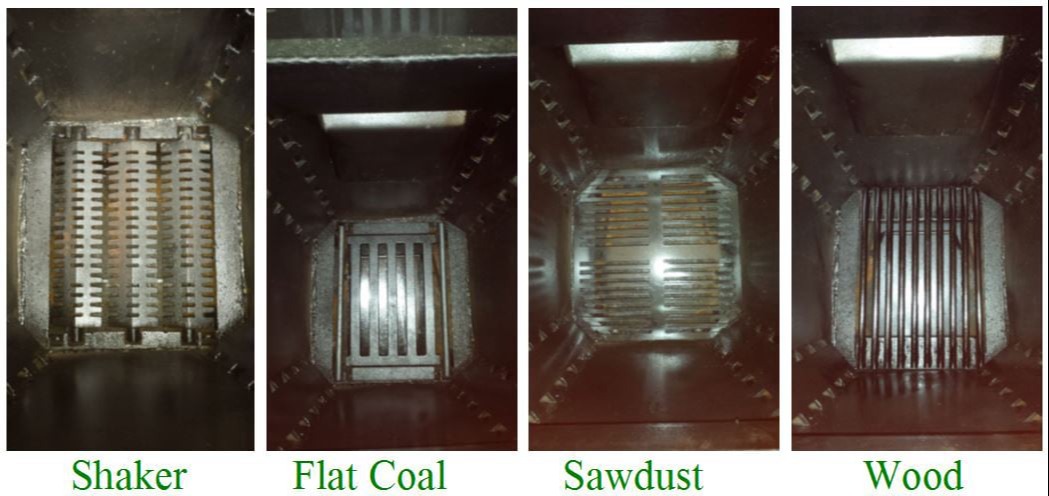

Four different grates available. ONE INCH SOLID FLAT STEEL IRON GRATE (coal) is standard.

43 door parts make up our 160 lb Hyprotherm door including TWO inches of

K-Factor Superwool

3/8'' formed firebox means NO WELDS between the vertical and horizontal pieces, which means MORE STRENGTH!

As you can see, the firebox AND water jacket are both made the same way!

This photo shows the Firebox, grates and chimney. This is a FLRH-350 Model with 3 grates. Other smaller models have one or two grates.

The oxygen is blowing up through these grates into the firebox like a blacksmith's forge; feeding oxygen into the fire from the bottom which is the way fires burn. You always get complete combustion with no unburnt wood, just fine ash left over.

The ashes fall down through the grates into the provided ash tray, which makes cleaning out the ashes a breeze. No opening the firebox door and being exposed to 800 F temperatures and having to kill the fire in order to shovel the ashes out. What is even worse, is having to start a fire again in the dead of winter!

The combination of the 75 CFM forced air induction blower and this unique chimney design is what give you in excess of 75% efficiency! This is getting very close to the claimed efficiency of these new EPA models that cost over $15,000. These EPA furnaces have a jet engine style burner in the bottom that requires special fuel; just like cars in the early 70s required unleaded gas - it was still gas but was special and required.

This "new" fuel is wood that has been dried for two years under cover, in order to obtain less than 20% moisture content. WHO DOES THAT? If you don't use this wood, your efficiency drops to about 50%.

Our chimney design is what gives us this high efficiency rating because it drops low in the firebox, trapping the gases that are in the wood so that they don't escape out the chimney and your boiler burns them up, every time it fires, extracting more energy from your wood.

Forced-air draft blower tube from the 75 CFM induction blower in back behind the door.

Our unique Hyprotherm designed water jacket and firebox; made with a 430-ton Press Brake; formed-steel with NO WELDS at the top corners!

This photo shows the firebox surrounded by water on the back, top and both sides. It also shows the chimney coming up through the water jacket, further heating up the water before exhausting into the air.

Full Sized Rear Door for super easy access to your pump(s), Ranco thermostat, water level gauge, blower motor, fan switch, analog thermometer and 110 outlets plus your hot water coil wiring and plumbing, which is all done for you.

COAL BURNING so very hot!

All of our furnaces and boilers burn coal because of the forced-air induction blower that is in the back, blowing oxygen into the bottom, which absolutely necessary for burning coal. Most furnaces have a fan on the front door or in the top of the firebox which will not work!

Most of our models have included cast iron grates which are designed specifically for burning coal but do an incredibly good job with wood as well.

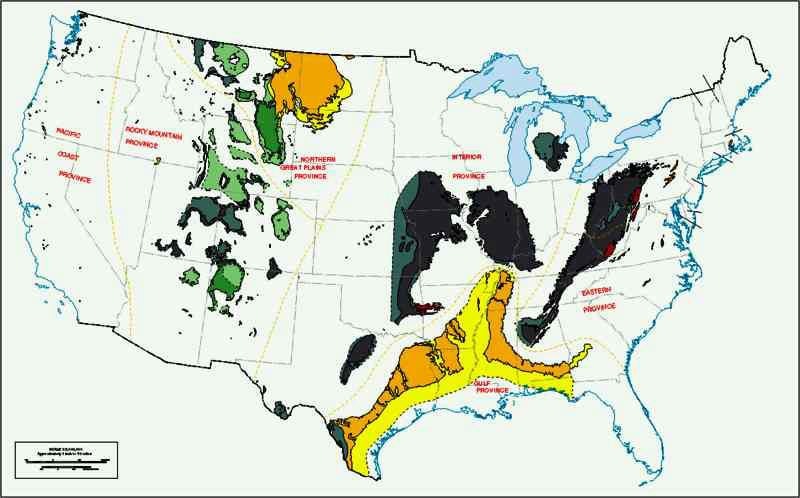

Coal Map Sources Available

Coal is available in many locations, even in my little town of 200,000 people, even though it is not sourced in our state. It is commonly available in easy to carry and load bags.

Hyprotherm Fill Valve and Overflow tube on side.

This valve on the front is piped to the rear of the boiler where it is plumbed into the domestic hot water coil, pulling hot water from your hot water heater to fill up the boiler.

Pick one day a week (like a Saturday) and simply open the valve and you will hear water running. Soon, you will see it running out of the overflow tube that you see on the side, just around the corner from the fill valve.