Outdoor wood boiler vs. outdoor wood furnace

How does a forced air wood furnace work

Comparison of an outdoor wood boiler vs outdoor wood furnace

- forced air (hot air) wood furnace

The main difference between the forced-air

furnace and a water furnace, is that air circulates around the firebox, instead

of water, so no pump is needed. A fan is used to circulate the air (which is

included, just like a pump is included on our boilers).

The forced-air furnace can only heat one building because there is only one

thermostat hookup and cannot heat your domestic hot water like the boiler can.

Any other building cannot be thermostatically controlled if both are to be the

same temperature (or with a damper).

A water furnace (outside boiler) can heat virtually unlimited buildings and more

than one hot water heater.

A forced-air furnace has to be relatively close your home because of the expense

of the pipe and the air flow losses, if it's too far away.

You could consider this an outdoor forced air wood furnace

review

Review of a wood or coal hot air furnace and how it compares to a wood or

coal boiler.

How does a forced air wood furnace work you ask?

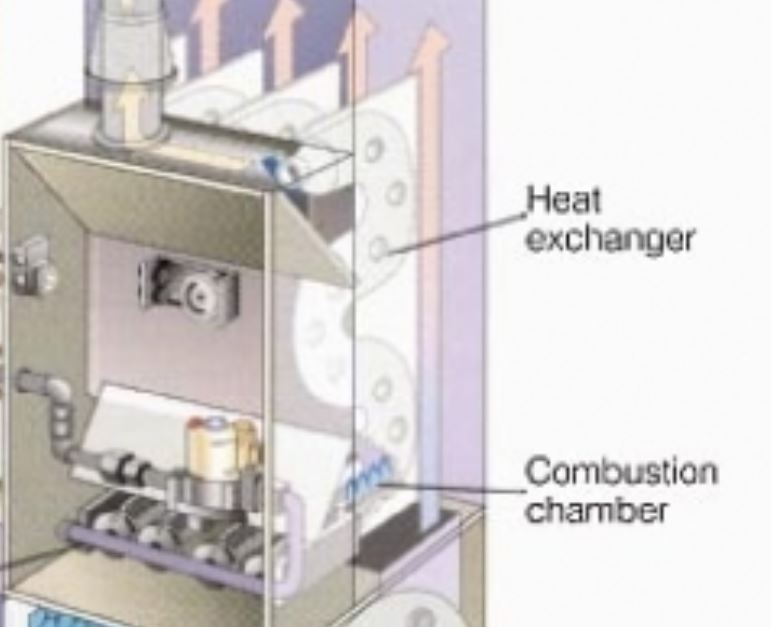

A forced air wood furnace heats up the firebox

and the air surrounding it, much like a traditional furnace will heat up a heat exchanger.

Heat exchanger in gas furnace

In a forced air furnace the firebox IS the heat exchanger,

only needing a big (2000 CFM) blower to blow hot air into your home.

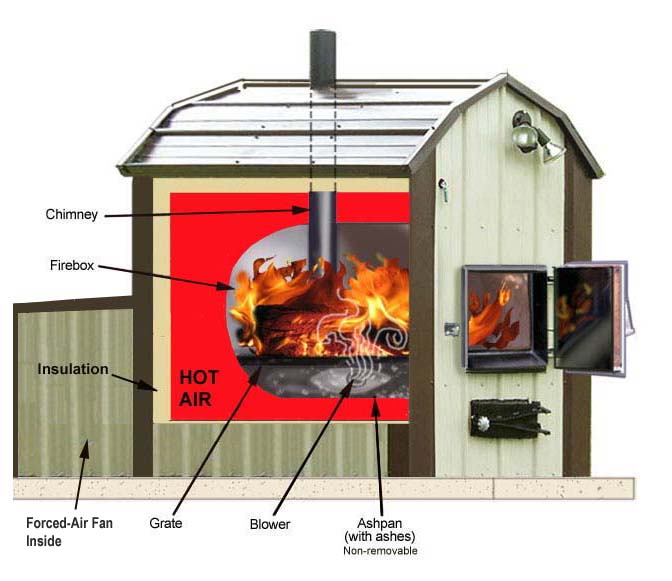

This image depicts the previous round firebox design. They are still built with

one piece of steel, the firebox formed formed with a 430-ton press brake.

The advantage of this configuration is less welds than a traditional firebox

which is a literal box; taking 12 welds to assemble six flat slabs of steel into

a box. Both the design above and the new firebox only has to have 2 welds

to weld the end plates on! The new design requires 2 more welds (but not

12!) to weld the firebox to the water jacket bottom. This enables you to

have a water jacket bottom the same thickness as the firebox. No one else

in the world does this!

One of the biggest differences it is in the operation. A water furnace will only

come on to heat up the water and it only does that every few hours and then will

shut off when the water reaches temperature. The fire would not ignite again

until the water temperature drops sufficiently to require it to be reheated.

By contrast, the forced air furnace operates just like an indoor furnace; it

will likely come on for 20 min. and then shut off for 20 min. and then come back

on for 20 min. and repeat. This causes somewhat more smoke than a water furnace

because that is the only time you have smoke (5 to 10 minutes); is when it is

building a fire.

Most people don't care because you have your doors and windows closed in the

winter and are rarely outside but I wanted to point that out, in case you have

kids playing outside in the winter time frequently.

You can use less expensive galvanized ducts but then it may not look as good

aesthetically (not hidden underground).

A forced-air furnace requires 2 ducts - supply and return; either standard

inexpensive duct, or two buried insulated 12" ducts. With the standard

inexpensive duct, it normally runs through a wall or window - and is visible,

unless a chase is built to house the ductwork, like the Army Corps of Enginers

did for their warehouse with one of our Hyprotherm hot air furnaces.

Ductwork from a Hot Air forced-air furnace through a basement window to the

existing ductwork.

The underground duct is $20 a foot and you need two ducts plus you will usually

need four elbows, which are $125 each. Clamps can be a total several hundred

dollars ($50 each), depending on how many you need. Min of 10 per pack.

You would use standard inexpensive round 12" metal duct to get from the

back of the furnace to the pipe in the ground. Read more and see pictures at http://www.outdoorwoodfurnaceboiler.com/FORCED-AIR-OUTSIDE-WOOD-BURNING-FURNACE.htm

The pipe is shipped from their factory. You can see info and videos at http://www.aqcind.com/the-blueduct/

Here is a photo of the insulated underground blue ductwork connected to our hot

air furnace and a mobile or modular home:

Flanges/adapters to connect the 12" round ductwork to you excising square

or rectangular duct/

Standard metal 12" duct is usually $3-5 a foot.

The only other items needed are 110V wire and a thermostat wire.

The furnace needs to be a min. of 5 feet from your home (according to U.L tests)

but ideally within 40 feet from your existing ductwork,

for less heat loss and air flow losses.

Blue Duct should be buried below the frost line because it is always 50-55 F, no

matter where you live, so that is like having the duct outside on a spring day

instead of in frigid winter temperatures; saving you a lot of energy and wood.

_________________________________________________

In case you haven't noticed, everyone says they are the best, so you have to

look at the facts and decide for yourself. Look at our weight, simplicity and

features combined with an unprecedented 20-year ON-SITE warranty make is the

best, I am sure you will agree.

Note that many furnaces don't have an ash

pan, forcing you to clean the ashes out of the firebox - while the fire is

burning (or you have to let it cool down).

There are no fancy (expensive) electronics or circuit boards to burn out at the

first power surge or electrical storm.

Our fan, on both the hot air furnace and the boiler (the blower

inducer, that feeds oxygen to the fire) is in the back and blows air up through

the grate, feeding oxygen into the fire from the bottom, just like a

blacksmith's forge - the best way! Many furnaces don't have a fan at all

and others have a fan on the front door, blowing air into the side of the fire,

not in from the bottom where it's needed.

Our chimney drops down in the firebox, trapping in the heat and gases, to

maximize heat transfer and ensuring you're not heating the outside air! This

huge secondary burn chamber that is created, allows you to burn off all the

gases that first ignite, when you throw in a new piece of wood. This is valuable

heat, normally lost.

This design is one of the reasons that we achieved the high efficiency rating!

Most other manufacturers have their chimney right at the top of the firebox,

allowing so much precious heat to escape!

One other thing is that these water-less hot air furnaces are 100% legal in 49

States because they are not boilers which most state laws and the Federal law

are against, for heating a residence.

Ben at WNC Stoves

828-683-0025 9 AM - 9 PM ET, 6 days a week

Remember, the 20 year parts AND labor ON-SITE warranty is probably the best

feature because at least 50% of the manufacturers out there require that you

ship the furnace back to the factory to get it repaired. Then they have to ship

it back and while the repair may be free, they charge you for the shipping both

ways AND you have to disconnect the furnace, reinstall it and be without it for

2-4 weeks.

Please find the installation manual at that link here:

http://www.outdoorwoodfurnaceboiler.com/INSTALLATION-INSTRUCTIONS-AIR-TO-AIR.doc

Please call with any and all questions!

Remember there is no sales tax when it is shipped to your home!

MENU

HOME/Index

All

about WNC Stoves

20-year

ON-SITE WARRANTY

Wood

Boiler for 2000 sq. foot house

Hyprotherm

Wood Boiler HOME | BENEFITS

of an Outdoor Wood Boiler | Outside

Wood Boiler FAQ

Outdoor Wood Boiler PICTURES | PURCHASE

and PRICES | Financing

| Layaway

Proper

Insulation in an outdoor wood boiler

SHIPPING a Wood Boiler | Outdoor

Coal Boilers | Wood

vs Electricity and Propane Costs |

BTU

of different Wood Species

INSTALLATION

| Installing

a Heat Exchanger

RADIANT Heat from a Wood Boiler

Stainless

Steel vs. Mild Steel in Outdoor Wood Furnaces

Smallest

Mini BOILER | Boiler

for 2000 sq. ft home |

Pool

Heater

Best

Outside Wood Boiler |

Wood-Fired

Air Conditioner COOLING! | Driveway

and Walkway Snow Melt

Top

Loader Boilers

BLOG - Outdoor

Wood Boiler Advantages

CONTACT

WNC Stoves - 6 DAYS a WEEK at 828-683-8055

SITE

MAP