A WORK IN PROGRESS

MORE COMING This Week!

This gives you a better idea of scale. Not as big as it looks above:

Look at Our Newly Designed Fireboxes

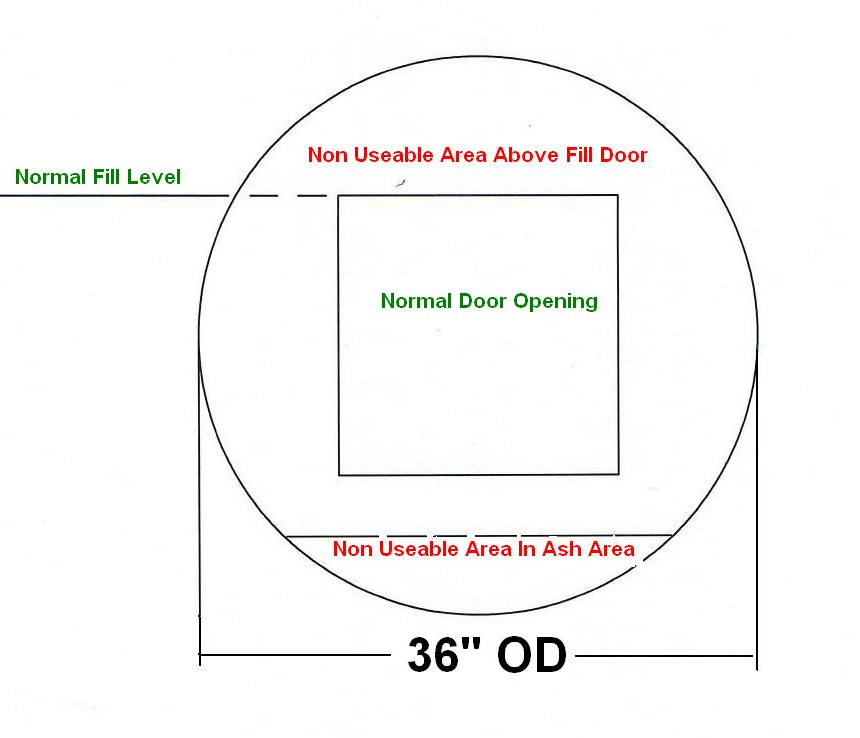

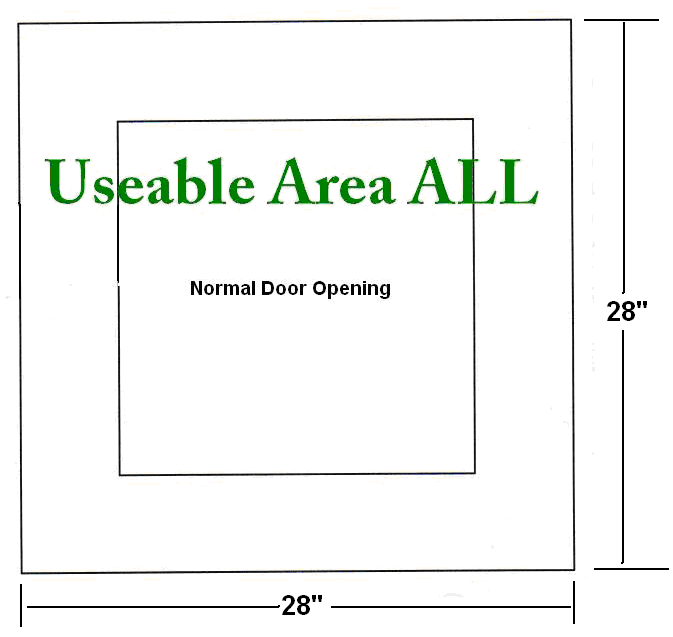

When we decided to reinvent the wheel we knew that we had to start at the beginning and to us that meant the firebox. That is why at the heart of every HyProTherm furnace is a firebox unlike any other in the industry. Based on the knowledge that fire naturally rises and as it does it creates currents of air, we designed our HyProTherm fireboxes to maximize this potential. By utilizing the upwards drafting, funnel shape of a tornado, we have created a furnace that will burn coal or wood with almost no assistance from a combustion blower. Not only that, but our design will burn green sawdust, shavings, pellets, corn, or virtually any biomass that you choose, and due to its shape it will burn more evenly, completely, and with less stirring of coals. It is also the only firebox that allows for the use of the entire firebox. Because there is no flue pipe in the way and by utilizing our top loading feed door our fireboxes hold more than a comparably sized horizontal firebox (as shown below).

OLD Traditional Design:

Standard Furnace (horizontal fire box)

radius* length

http://www.calculatoredge.com/enggcalc/volume.html#cylinder

PS - 140 = 13.00 CF (useable) 16.15 CF (total, non useable)

Horizontal 36 OD @ 28 deep,

125 gallon cap

TW-1000 = 12.81 CF (useable) 15.31 CF (total, non useable)

Horizontal @ 27.5 deep

____________________________________

NEW Design:

Standard HyProTherm (VERTICAL FIREBOX)

width*length*height

http://www.calculatoredge.com/enggcalc/volume.html#cylinder

HT- 3500 = 12.48 CF (useable) 12.48 (total

useable)

125 gallon water cap

Firebox

and Grates

From:

Charles C. Cottrell

VP,

Technical Services

North

American Insulation Manufacturers Association

To

Hyprotherm Manufacturing: Points of interest 1-4

1.

In reviewing your request on your Forced Air Models and your commercial Hydronic

models.

We

know you feel a need for a desired product.

There

are a number of materials that would work for your commercial hydronic and

forced air stove. The high temperature fiberglass you cite below is one; there

are also fiberglass and rock wool (which has a higher melting temperature) and

the ceramic fiber materials (very high temp).

2.

In our opinion you will need.

For

the project youre looking at I think max operating temperature and corrosion

resistance would be important as well as workability. Blanket materials are more

flexible than boards and blocks.

3.

There are products you should not use for a thermal cycling unit.

Do

not use a standard fiberglass insulation meaning the standard fiberglass your

using is just metal building insulation with an R factor on it tested at 75

degrees, exceeding that perimeter heat factor the R factor drops dramatically

4.

Results to following proper recommendations.

Based

on our knowledge and the understanding of your needs, by using our

recommendations and HVAC normal codes per efficiency, you should get the results

you desire.

Thank

you for your eagerness to do all you can to manufacture the best product

available.

North

American Insulation Manufacturers Association

Charles C. Cottrell

New HYPROTHERM

Improved Style Insulation

HyProTherm

Standard Insulation Package

Based on the

NAIMA formula thickness / k value = R

value

Three inches

of Knauf ET Blanket = R 10.71

+

One quarter inch Solar Guard = R 11.6____

HyProTherm side

wall standard insulation = R

22.31

note: operating parameters,

temp -10 deg, 5 mph wind, 150 deg operating temp = -1.6 deg

8.4 deg differences (wow) see

chart below

Two inches of

Morgan Super Wool Blanket

HyProTherm top standard insulation

note: operating parameters,

temp -10 deg, 5 mph wind, 700 deg interface temp = 22 deg cold face temp

Features and

Benefits

Excellent Thermal Properties

Low thermal conductivity.

Increase system efficiency and decrease fuel

usage.

Low-Cost Installation

Lightweight and easy to handle and fabricate.

Flexibility makes them ideal for flat or

irregular surfaces.

Damage Resistant

More resistant to abuse than standard ET

Blanket.

Tough and resilient.

Resist damage in shipment, and during and

after installation.

Easy opening, Gas Spring Assisted Top

Loading Fuel Feed Door

|

Model

Name |

RS-4500 |

|

Coal

COMMERCIAL

GRADE for Residential |

Coal |

|

Price: |

Regular

$6,900 Special

Introductory Price: $6,495) LESS

$700.00 = $5795 |

|

Fire

Box Cubic Feet

(total) |

15.31 |

|

Fire

Box Cubic Feet

(useable) |

15.31 |

|

Burn

Area Sq |

31x

28.25 |

|

Fire

Box Thickness |

3/8 |

|

Grate

System |

Shaker |

|

Water

Capacity Capacity |

182

gal |

|

Water

Jacket

Thickness (sides,

top) |

3/16″ |

|

Water

Jacket Thickness (bottom) |

3/8 |

|

BTU |

203,900 |

|

Heating

Area Sq |

4,500 |

|

Fuel

Door |

24

x 24 |

|

Ash

Door |

yes |

|

Removable

Ash Pan |

yes |

|

Warranty |

20

yr |

|

Pump

Included |

yes |